Definition

The duty cycle is defined according to NF EN 60034-1 standard. It concerns the rotating electric machines, which means every machine that uses an electric motor. This standard describes the use of conditions to prevent motor deterioration.

Application

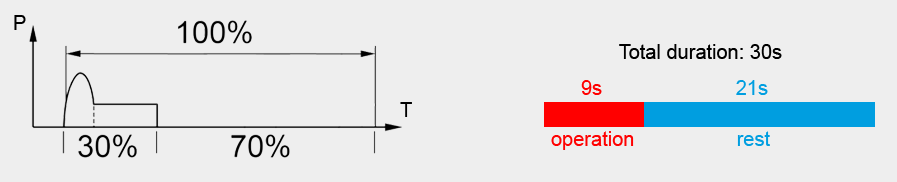

Valpes actuators correspond to a category whose name is S4 service: periodic intermittent running with a start-up. The functioning corresponds to a succession of cycles including a start-up period, an operating time with constant load, and a non-powered rest time.

Phase 1: the start-up period corresponds to the motor acceleration time, until striking the “speed / constrain” balance. During this period, it will produce a significant starting current (see the topic “What are the starting currents” in this FAQ).

Phase 2: the operating time corresponds to the normal use of the apparatus. During this period, the motor temperature will increase but must remain below the temperature defined by the insulation class of the motor (see topic in this FAQ).

N.B. : a periodic service includes that the motor will not reach its thermal balance during the operating time.

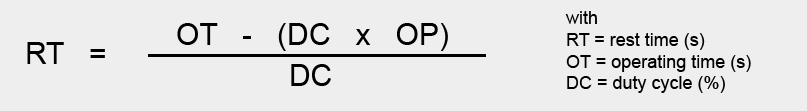

Phase 3: to get a lower temperature, the motor needs a rest time. This duration is calculated according to the duty cycle (expressed as a percentage) as per the formula:

Example with an ER PREMIER 20Nm :

The operating time is 9s and the duty cycle is 30%.

The rest time is (9 – (0,3*9))/0,3 = 21 seconds. The total duration of the operation is 9 + 21 = 30 seconds.