Optimising Pneumatic Operated Valve (POV) Solutions for a Leading Equipment Manufacturer in China

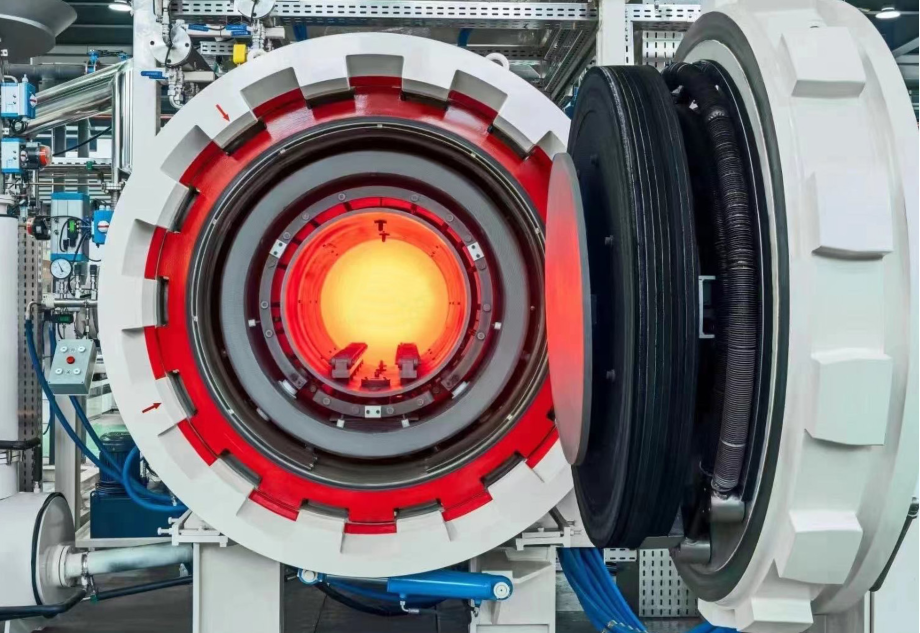

At BAR, our customers rely on us to identify solutions to their fluid control challenges. This customer was undertaking work to enhance the performance and reliability of their Pressure Sintering Furnaces. Previous experiences with other component manufacturers revealed cost and reliability challenges. Seeking alternatives, they turned to bar to provide innovative solutions that could address their specific needs while offering greater value.

SCOPE: Optimising Pressure Sintering Furnaces Performance.

WHO: A leading equipment manufacturer specializing in the production of Pressure Sintering Furnaces.

WHAT: Production and optimization of Pressure Sintering Furnaces, crucial equipment utilized in various industrial processes.

HOW: A range of products, including pneumatic operated ball and butterfly valves equipped with limit switch boxes and positioners.

WHERE: China

WHEN: Began in 2018 and continues to evolve with ongoing upgrades

Solving Challenges with our Pneumatic Operated Valve (POV) Solutions

The primary challenges faced by the manufacturer included high costs associated with solenoid valves and recurring issues with positioners. Additionally, they sought to streamline their operations and minimize downtime caused by equipment failures. The customer’s objectives were clear: reduce costs without compromising quality and improve the reliability and efficiency of their furnaces.

Our team worked closely with them to identify suitable alternatives to address their challenges. We recommended using the NM-521-H solenoid valve to replace the original valve with a solution that is easier to install at a similar price point. This conversion helped the manufacturer save installation time and labor without compromising product performance and cost.

A comprehensive testing process was conducted to address the reliability issues with positioners, identifying the need to change the Positurn 2 and Positrol positioners. The Positurn2 and Positrol positioners are assembled directly connected to the Actubar actuator. There is no need for a bracket in between, saving installation space and making the structure more compact.

In addition, the built-in solenoid valve design requires no pipeline connection, reducing the air leakage points.

This change ensured greater reliability for the customer and minimized the occurrence of equipment failures, leading to improved overall performance and reduced maintenance costs.

Our Solution

To meet these objectives, we proposed the Pneumatic Ball Valve with Actuator PKO-3/2-040-D068 from our product range, which offers a range of benefits. The pneumatic actuator allows automated valve control based on predetermined signals, eliminating manual intervention and enhancing precision in nitrogen flow control.

Designed for industrial applications, the actuator and valve ensure long-term reliability and durability. Automation reduces the risk of human error, enhances safety, and ensures compliance with stringent food processing standards. This system also improved operational efficiency by maintaining a consistent nitrogen supply, enhancing productivity, and reducing production costs.