Our customer faced a significant challenge in maintaining optimal temperature control in their roastery application. The high temperatures required for roasting coffee beans demanded a reliable and efficient solution. The previous manual system was insufficient, leading to inconsistent roasting results and operational inefficiencies. The company required an automated, high-temperature solution to ensure consistent quality and efficiency.

SCOPE: Delivering optimal roastery temperature control

WHO: Premium coffee producer

WHAT: Roastery temperature control

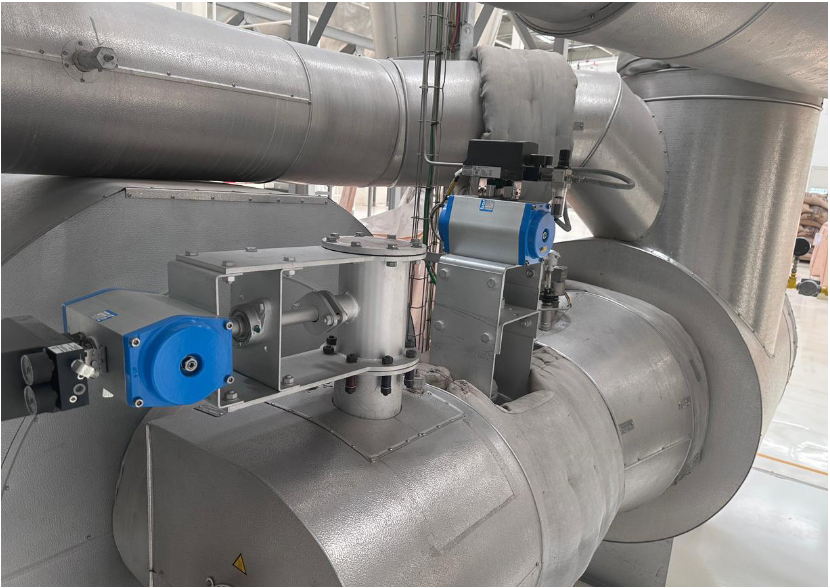

HOW: Pneumatic Ball Valve with High-Temperature Bar GmbH Actuator + bar-switch control

WHERE: Dubai, UAE

WHEN: 2017 – Present

High Temperature Challenges

Delivering a consistent, reliable solution that could operate efficiently was essential for our customers. Operating in Dubai’s dynamic and competitive market environment, they continuously innovate to stay ahead. Their adoption of advanced temperature control technology highlights their commitment to maintaining a competitive edge through innovation and efficiency, and our actuator now plays a key role in successfully implementing this technology.

Our Solution

The pneumatic ball valve with a high-temperature bar GmbH actuator was selected to meet our customer’s needs. The system was customized to seamlessly integrate with the customer’s infrastructure, with the actuator calibrated to ensure precise temperature control in the roasting process. Designed for extreme conditions, it has operated reliably since its installation in 2017 without failure.

Temperature control automation reduces human error, enhancing safety by maintaining optimal temperatures and preventing overheating. Additionally, it resulted in significant cost savings by reducing labor costs and energy consumption, and optimizing airflow only when necessary. The system improved operational efficiency by maintaining consistent roasting temperatures, producing higher-quality products, and reducing waste.